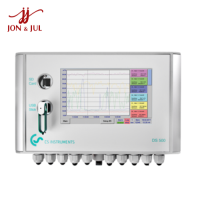

OIL-Check 400 0699 0070 Máy đo hàm lượng dầu dư Đo chất lượng khí nén theo ISO 8573

Giá bán: Liên hệ

Hãng sản xuất: CS-Instruments

Danh mục: Dòng đầu đo và cảm biến nhiệt độ

Nhà cung cấp: Jon&Jul Việt Nam

Xuất sứ: Đức

Ứng dụng sản phẩm: Cơ khí, Điện tử, Phụ kiện, Thiết bị tự động hóa, Ứng dụng kiểm soát vị trí

Residual oil content meter – OIL-Check 400 measures compressed air quality according to ISO 8573

General information

Residual oil content meter – OIL-Check 400

For long-term and highly accurate measurement of residual oil vapor content from 0.001 mg/m³ to 2.5 mg/m³.

Due to the low detection limit of 0.001 mg/m³, compressed air quality class 1 (ISO 8573) can be monitored.

Monitoring system for accurate and long-term measurement of vapor concentration Residual oil content in compressed air

Advantage

Permanent, highly accurate measurement of residual oil (oil vapor) with PID sensor (optical ion detector)

Ideal for mobile measurements: The PID sensor is ready to measure within approximately 30 minutes

Measure results with long-term stability due to automatic zero point calibration.

The integrated mini-catalyst reliably generates a defined reference gas for zero point calibration

In contrast to measurement systems that generate “zero air” or reference gas using an activated carbon filter and are therefore dependent on the aging and saturation of the activated carbon filter, the mini-catalyst produces out “zero air” without aging or abrasion.

No need to replace the activated carbon filter

Easy sampling through PTFE tube or stainless steel tube

Product Description

OIL-Check 400 – measures residual oil vapor content from 0.001…2.5 mg/m³, 3…16 bar.

High precision PID sensor, integrated mini catalyst for zero point calibration, no integrated display, with 0…10 volt analog output for connection to external chart recorder

Optional: The DS 400 chart recorder is integrated into the OIL-Check 400

OIL-Check 400 sampling system

Sampling system includes ½" ball valve (oil and grease free), 1 m 6x1 mm stainless steel tube (oil and grease free), clamping screw (oil and grease free) Z699 0075

Portable sampling system consisting of 2 m long PTFE hose, quick coupling (oil and grease free) Z699 0074

For systems > 16 bar: Pressure reducer (oil and grease free), maximum inlet pressure 300 bar, outlet pressure up to 10 bar

The included accessories

OIL-Check 400 Sampling System: Sampling system includes ½" ball valve (oil and grease free), 1 m 6x1 mm stainless steel tube (oil and grease free), clamping screw (oil and grease free) Z699 0075

OIL-Check 400 – measures residual oil vapor content from 0.001…2.5 mg/m³, 3…16 bar. High precision PID sensor, integrated mini catalyst for zero point calibration, without integrated display, with 0…10 volt analog output for connection to external chart recorder 0699 0070

Optional: DS 400 chart recorder integrated into OIL-Check 400 Z699 0071

OIL-Check 400 Sampling System: Sampling system includes ½" ball valve (oil and grease free), 1 m long 6x1 mm stainless steel tube (oil and grease free), clamping screw (oil free) and grease) Z699 0075

Portable sampling system consisting of 2 m long PTFE hose, quick coupling (oil and grease free) Z699 0074

For systems > 16 bar: Grease-free pressure reducer (with oil and grease), maximum inlet pressure 300 bar, outlet pressure up to 10 bar Z699 0076

Optional for DS 400: Integrated data logger for 100 million measurement values Z500 4002

Integrated Ethernet and RS 485 interface Z500 4004 Integrated web server Z500 4005

2 additional sensor inputs for analog sensors (pressure sensors, temperature sensors, etc.) Z500 4001

CS Basic - evaluate data in graphic and tabular form - read measured data via USB or Ethernet.License for 2 workplaces 0554 8040

See more technical documents here

See more technical products here

-------------

Communications

Phone number: 0348097237

Email: Tu@jon-jul.com

Address: No. 4, Street 14, Highway 13, Van Phuc Urban Area, Hiep Binh Phuoc Ward, Thu Duc City, Ho Chi Minh City, Vietnam